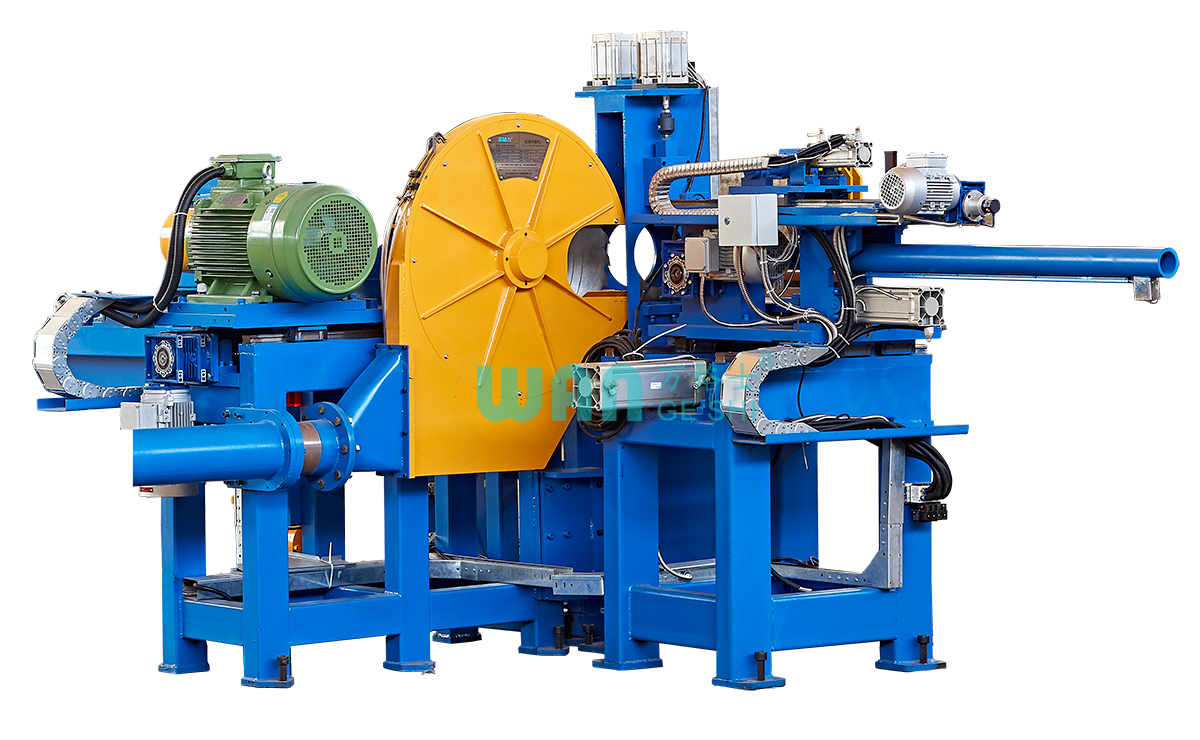

Uses: It is mainly used to cut off the larger diameter of aluminum rods, or to replace the hot shears in the occasions where the processing requirements of shearing aluminum rods are high.

Advantage

Compared with hot shear, large diameter aluminum rods can be sawed, and hot saws with a diameter of 550 mm aluminum rods have been designed and manufactured;

The sawing surface has flatness, verticality, high finish, and the hot shear cannot be compared;

The deformation of the aluminum rod during the sawing process is smaller than that of the hot shearing machine, and there is almost no deformation; if the peeling machine is combined, the outer oxide layer can be peeled off well;

The length of the saw is more accurate than the hot shear, up to ±1MM;

The replacement of the saw blade is very convenient, and it can be used directly without adjustment after replacement.

Can be equipped with a short rod to improve the yield of the product

Can process aluminum rods of different diameters without changing tools

Reduce extrusion time and increase production

Reduce bubble generation

The sawing plane has a high verticality and is flat, so that the plane of the mold is evenly stressed, which improves its life.